PDF] Behaviour of Bi-Adhesive in Double-Strap Joint with Embedded Patch Subjected to Bending

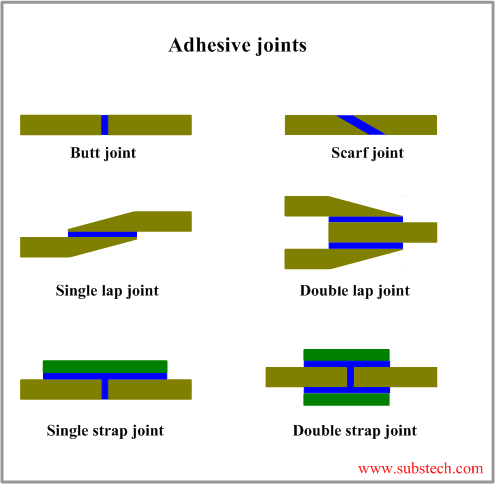

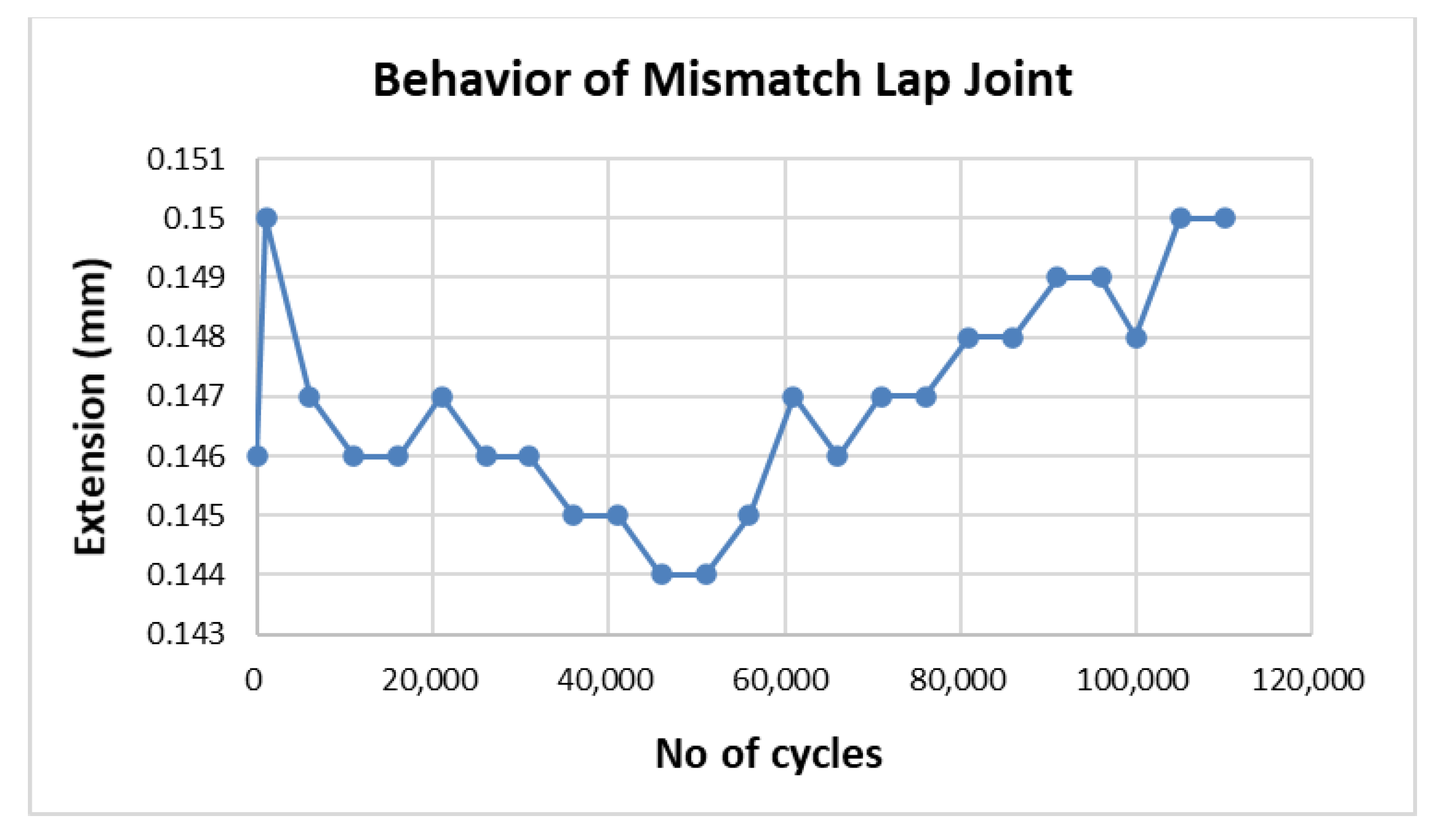

Abstract In this study, behaviour of bi-adhesive used in the repair of damaged parts was analyzed, using the finite element method. In a double-strap joint with an embedded patch, patch is embedded into the adherents for structural requirements. In addition, to increase the strength of the joint, two adhesives are used to bond the adherents. This approach reduces stress concentration at the overlap ends, increases the load capacity and delays the failure. These effects give rise to higher joint strength. For this purpose, a stiff adhesive, FM73 produced by Cytec Fiberite, was applied in the middle portion of the overlap, while a softer adhesive, SBT9244 from 3M, was applied towards the edges, prone to stress concentrations. Non-linear finite element analyses were carried out to predict the failure loads, to assist with the geometric design and to identify effective ratios of sizes to maximize joint strength.

Creep behaviour and tensile response of adhesively bonded polyethylene joints: Single-Lap and Double-Strap - ScienceDirect

A review on bi-adhesive joints: Benefits and challenges - ScienceDirect

A review on bi-adhesive joints: Benefits and challenges - ScienceDirect

PDF) Mechanics of Advanced Materials and Structures

Mechanical behavior of butt curved adhesive joints subjected to bending

PDF] Behaviour of Bi-Adhesive in Double-Strap Joint with Embedded Patch Subjected to Bending

A review on bi-adhesive joints: Benefits and challenges - ScienceDirect

PDF) Adhesively Bonded Carbon/Titanium Joints Under In-plane and Bending Loads

Materials, Free Full-Text

PDF) Stress Analysis of Adhesively Bonded Double Strap Joints with or Without Intermediate Part Subjected to Tensile Loading