Snap Fits Enable Plastic Parts Assembly, 2014-04-01, Assembly Magazine

To the casual observer, large piles of car parts are trash. But to an engineer looking to improve automotive design, they are a treasure. Such was the case at General Motors’ Competitive Assessment Center in Warren, MI, in the late 1980s. “There were enough parts from disassembled cars on tables to fill three football fields,” recalls Paul Tres, principal and founder of ETS Inc., a plastics engineering consulting firm. “The place was nicknamed Mona Lisa because the parts were hung up like paintings for competitive . . .

To the casual observer, large piles of car parts are trash.

US20070045379A1 - Staple cartridges for forming staples having differing formed staple heights - Google Patents

CN1923147B - Staple cartridges for forming staples having differing formed staple heights - Google Patents

US9486214B2 - Motor driven surgical fastener device with switching system configured to prevent firing initiation until activated - Google Patents

Akash Muralidharan on LinkedIn: 🔹 Snap fits are most economical and rapid methods of assembly for high…

US11317917B2 - Surgical stapling system comprising a lockable firing assembly - Google Patents

EP3613362A2 - Reinforced deformable anvil tip for surgical stapler anvil - Google Patents

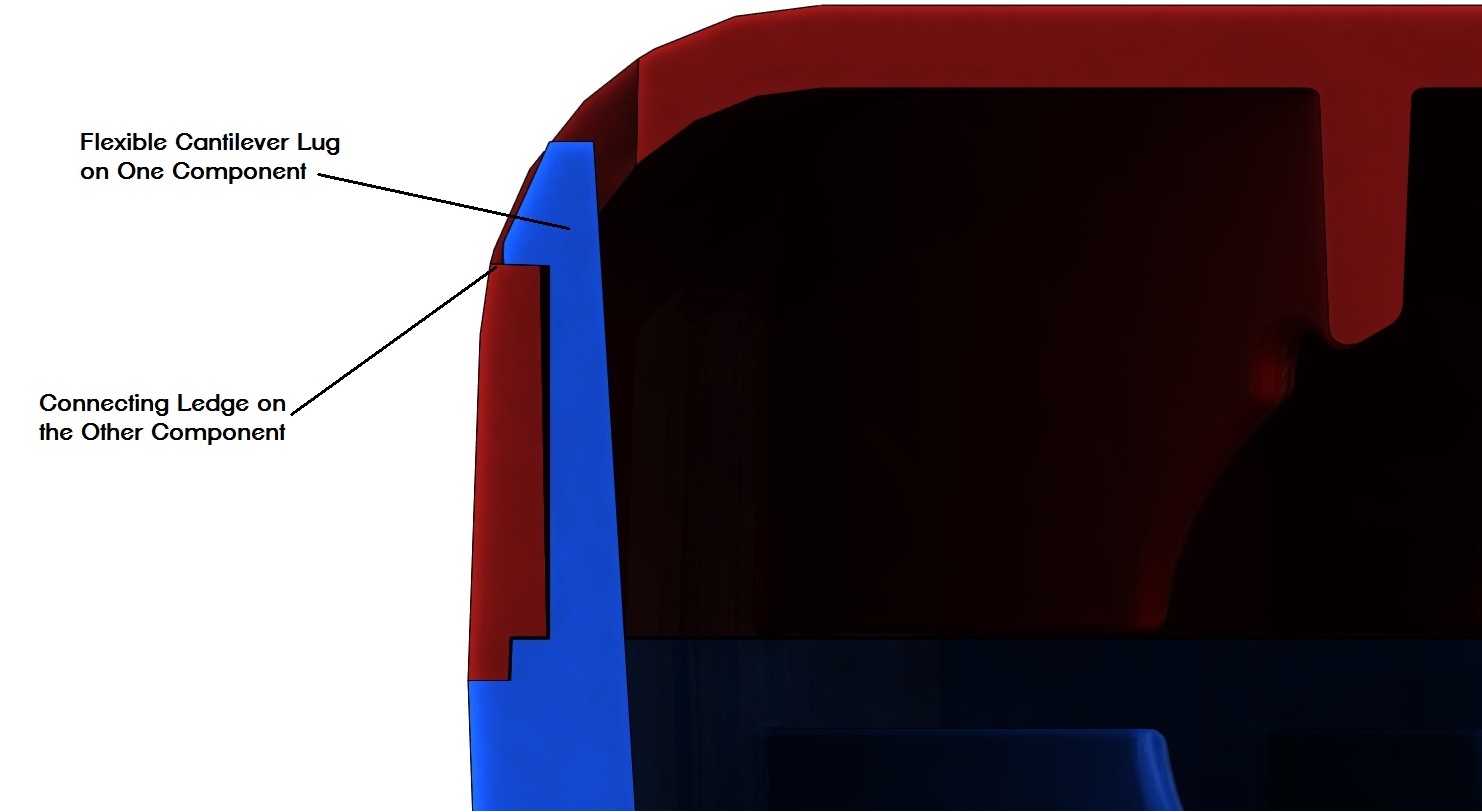

How to Design Snap Fit Joints in Plastic Parts - SMLease Design

DFA – Simple Mechanical Assembly Techniques for Plastic Parts

[Bonenberger, Paul R.] on . *FREE* shipping on qualifying offers. The First Snap-Fit Handbook : Creating Attachments for Plastics Parts

The First Snap-Fit Handbook : Creating Attachments for Plastics Parts

US10211586B2 - Surgical shaft assemblies with watertight housings - Google Patents

EP3042617A2 - Locking arrangements for detachable shaft assemblies with articulatable surgical end effectors - Google Patents