Polymers, Free Full-Text

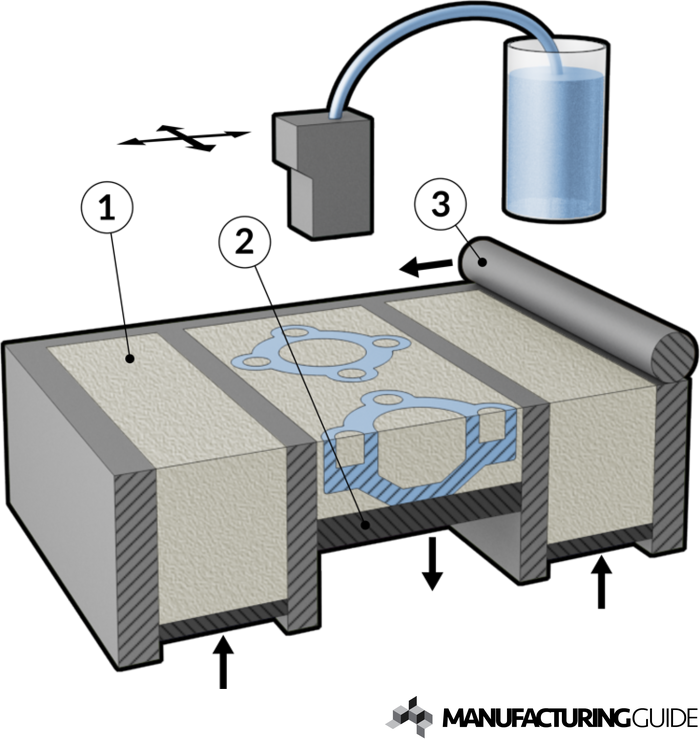

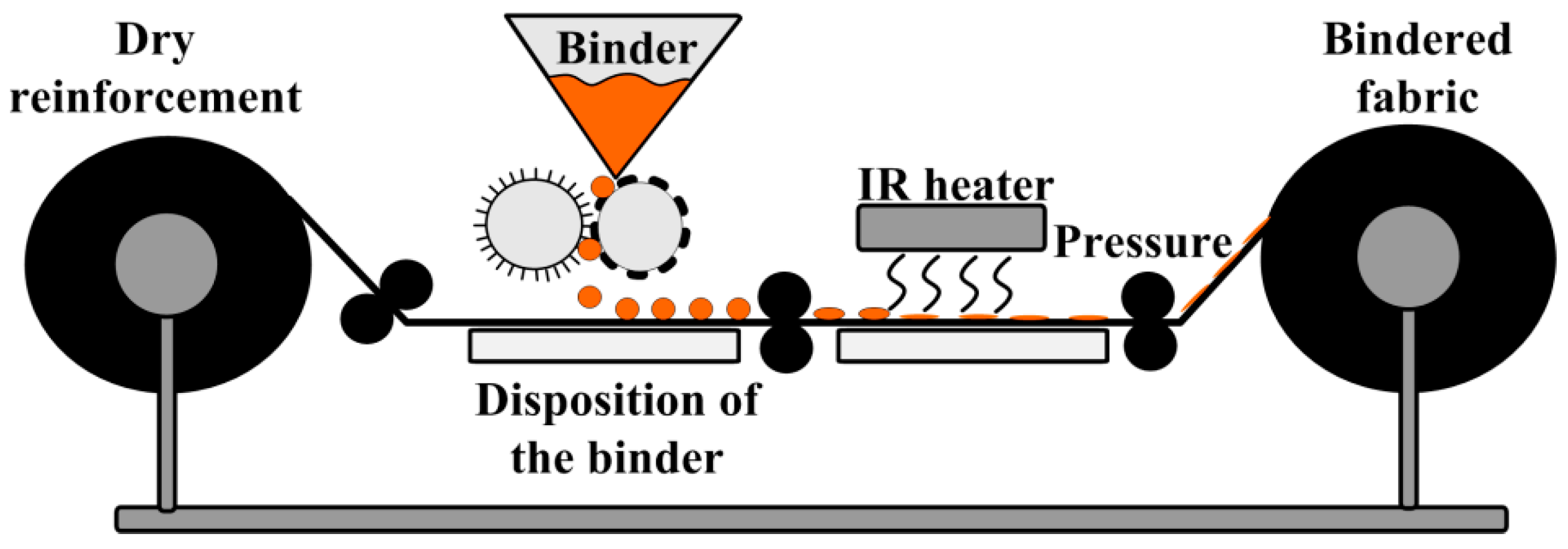

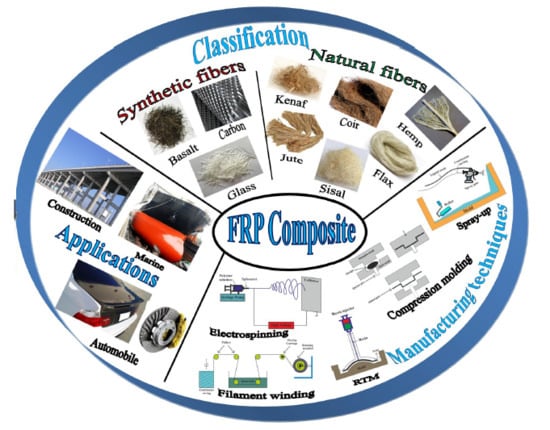

Binders, or tackifiers, have become widespread in the production of new composite materials by liquid composite molding (LCM) techniques due to their ability to stabilize preforms during laying-up and impregnation, as well as to improve fracture toughness of the obtained composites, which is very important in aviation, automotive, ship manufacturing, etc. Furthermore, they can be used in modern methods of automatic laying of dry fibers into preforms, which significantly reduces the labor cost of the manufacturing process. In this article, we review the existing research from the 1960s of the 20th century to the present days in the field of creation and properties of binders used to bond various layers of preforms in the manufacturing of composite materials by LCM methods to summarize and synthesize knowledge on these issues. Different binders based on epoxy, polyester, and a number of other resins compatible with the corresponding polymer matrices are considered in the article. The influence of binders on the preforming process, various properties of obtained preforms, including compaction, stability, and permeability, as well as the main characteristics of composite materials obtained by various LCM methods and the advantages and disadvantages of this technology have been also highlighted.

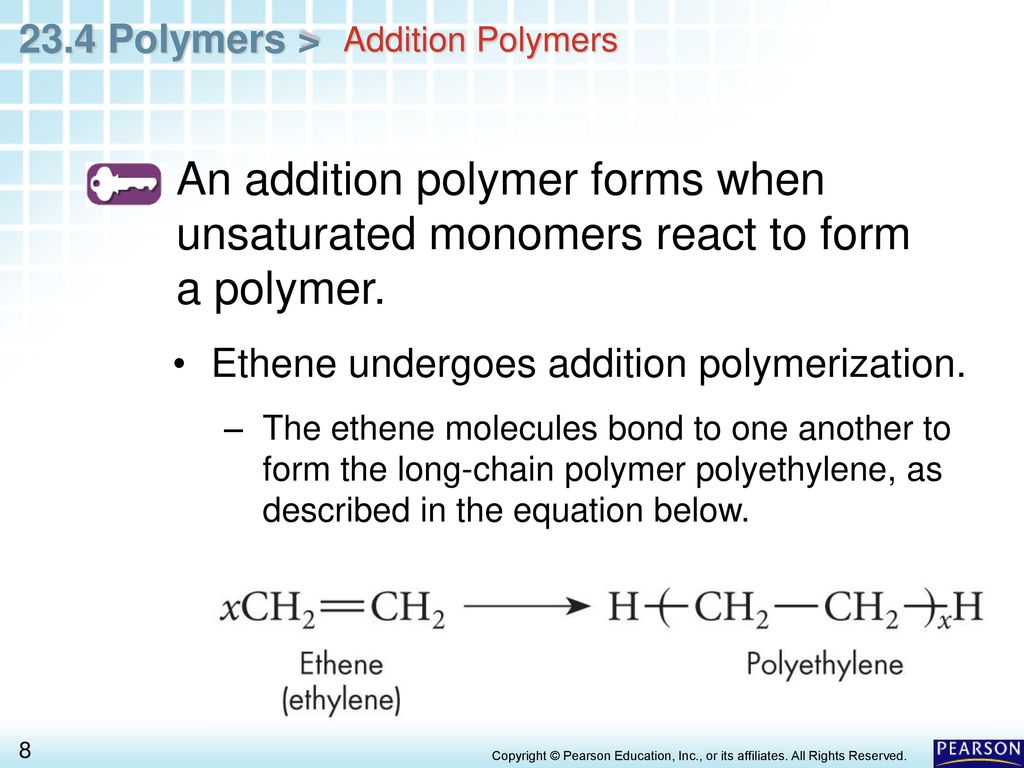

Addition Polymerization - an overview

Polymers, Free Full-Text

PDF) Aryl Polyphosphonates: Useful Halogen-Free Flame Retardants

Polymers, Free Full-Text, passfeder 5mm

Polymers, Free Full-Text, benny watts x reader

Polymers, Free Full-Text, 3d Printer Lubricant

Polymers, Free Full-Text

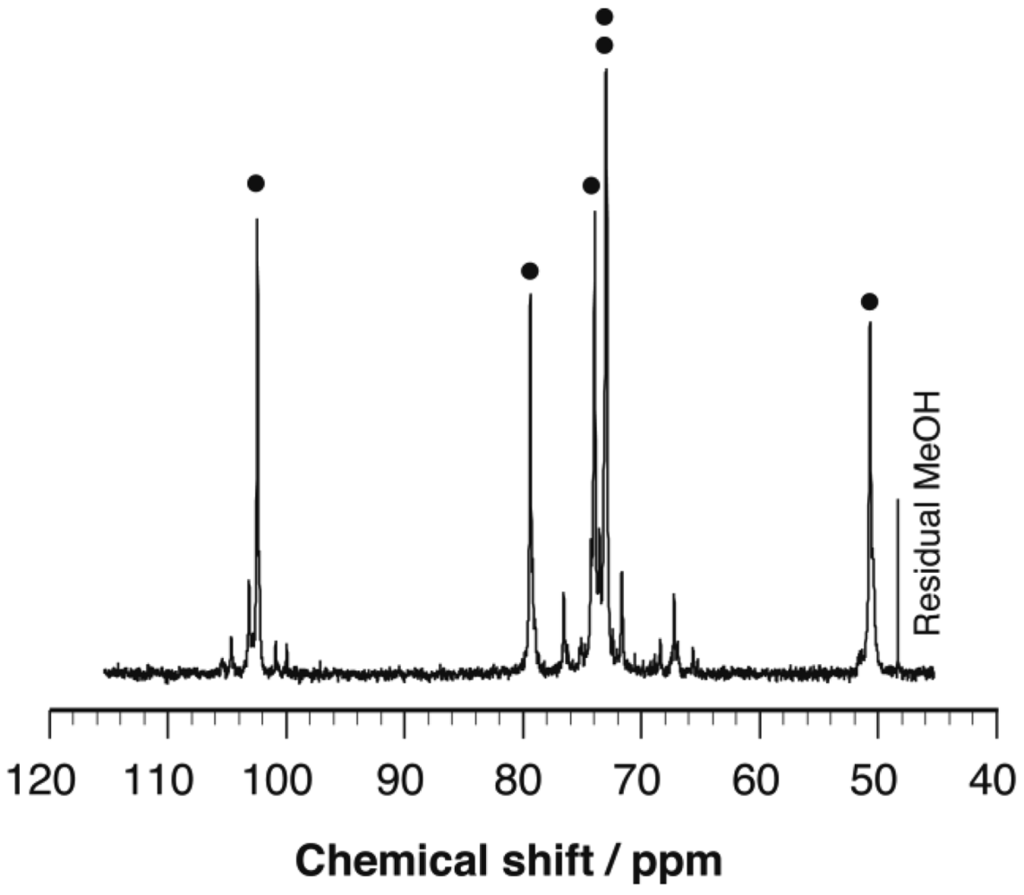

Membranes with artificial free-volume for biofuel production

Polymers, Free Full-Text

Polymers, Free Full-Text

Polymers, Free Full-Text

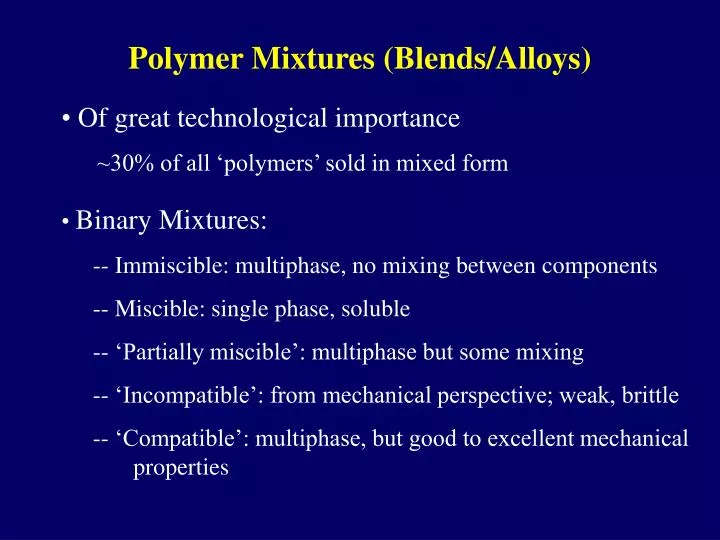

Polymers. - ppt video online download

PPT - Polymer Mixtures (Blends/Alloys) PowerPoint Presentation