Binders Used for the Manufacturing of Composite Materials

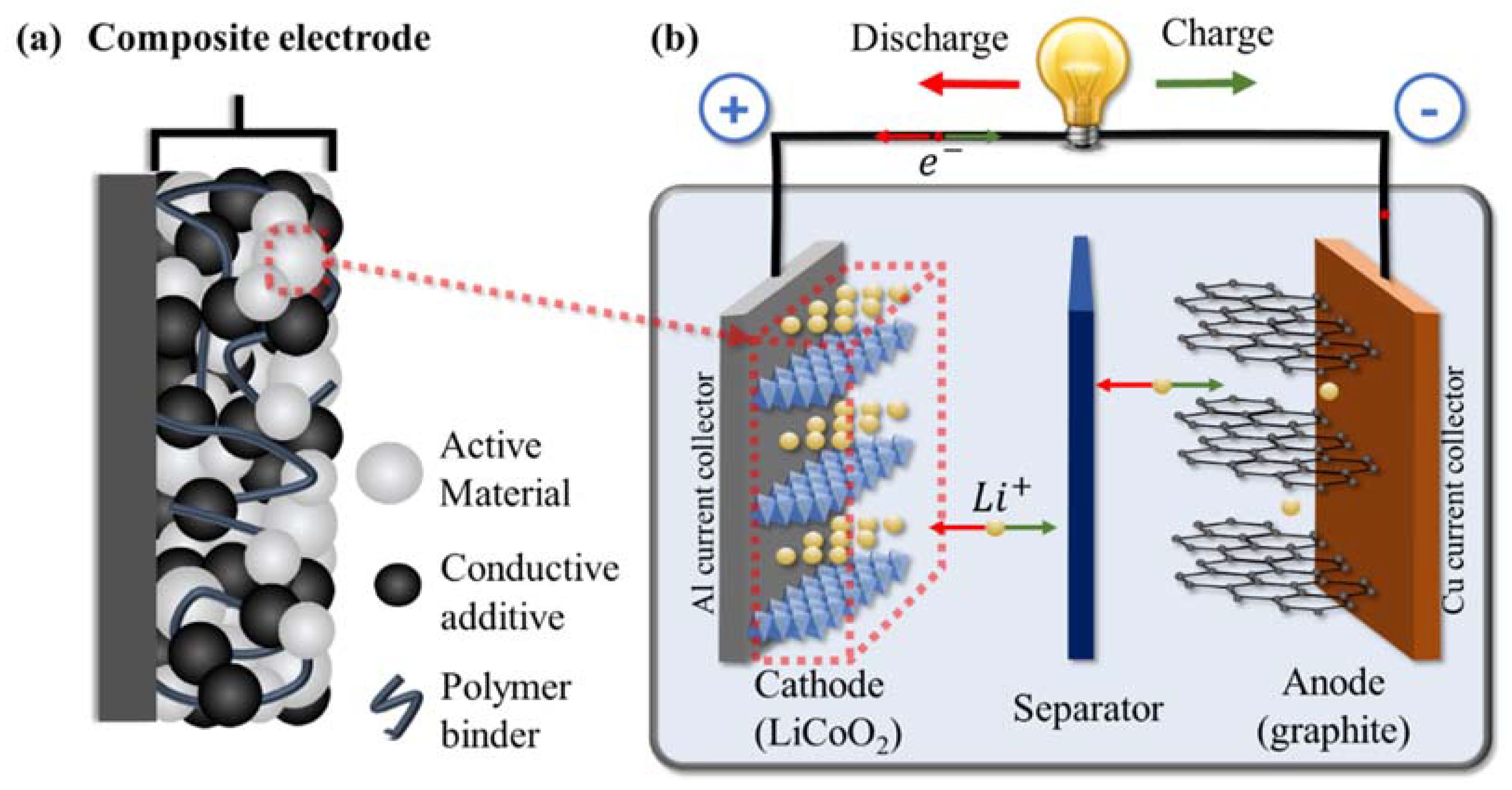

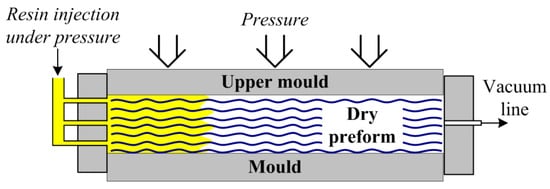

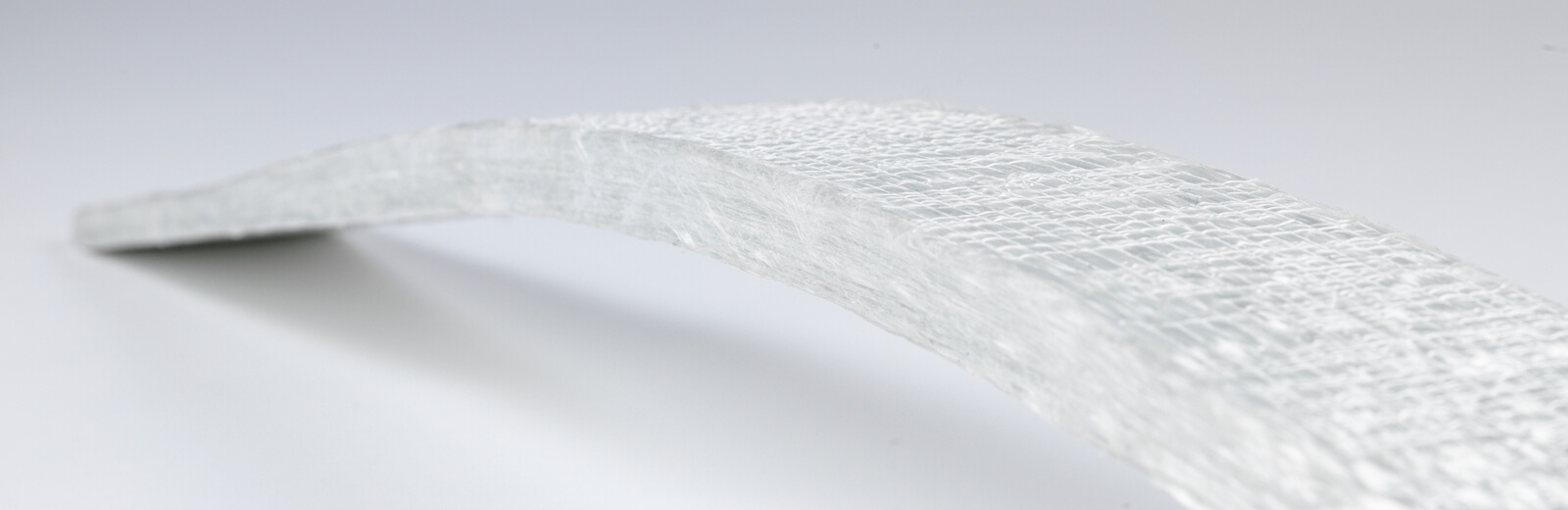

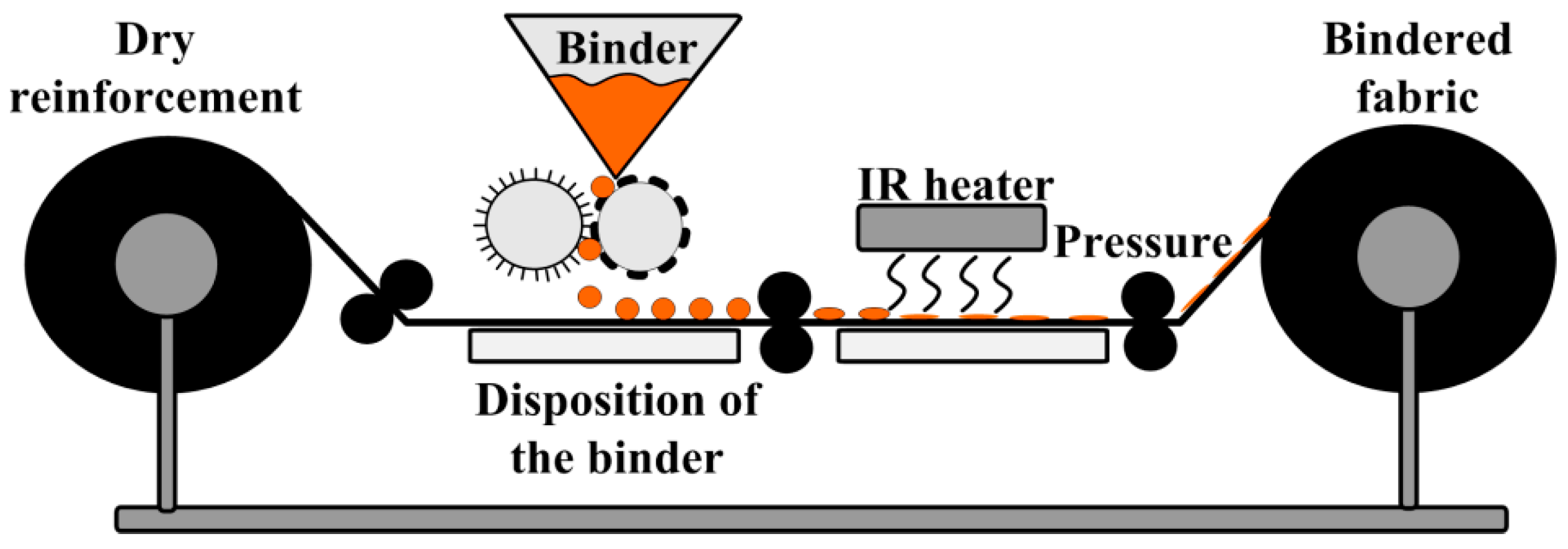

Binders, or tackifiers, have become widespread in the production of new composite materials by liquid composite molding (LCM) techniques due to their ability to stabilize preforms during laying-up and impregnation, as well as to improve fracture toughness of the obtained composites, which is very important in aviation, automotive, ship manufacturing, etc. Furthermore, they can be used in modern methods of automatic laying of dry fibers into preforms, which significantly reduces the labor cost of the manufacturing process.

Binder Jetting Additive Manufacturing for Industrial Applications

Technology For Prepreg Production PDF, PDF, Polymers

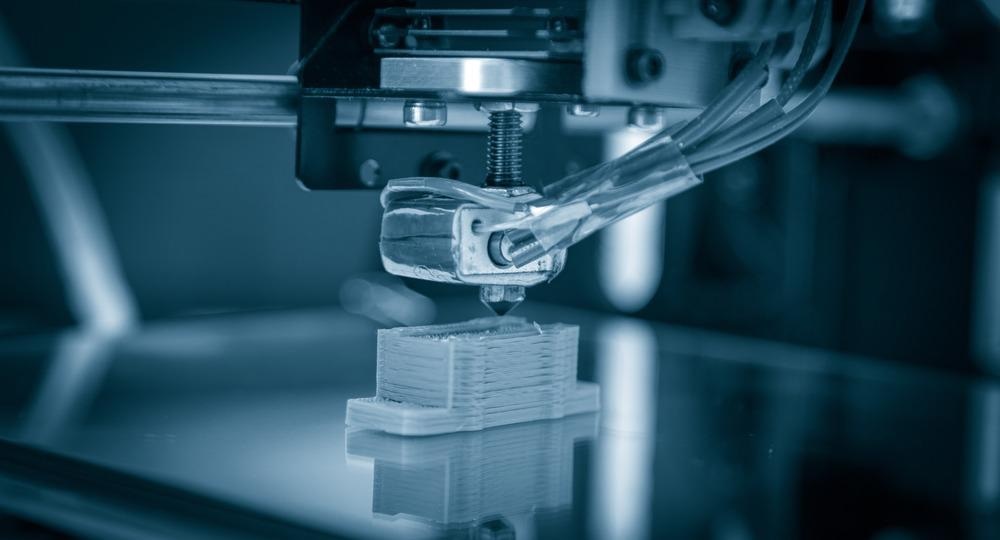

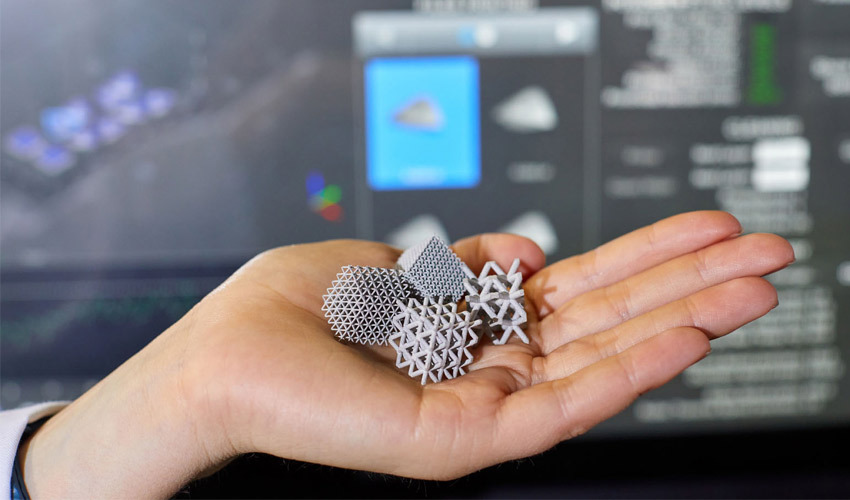

All About Binder Jetting 3D Printing

Influence of a Binder Composition Containing Diaplast Phenoxy Thermoplastic Resin on Properties of a Low-Viscosity Resin for Injection Technologies

Green Building – Composite Lumber

Preforming Process Huntsman Transportation

PDF] Optimizing Bladder Resin Transfer Molding Process to Manufacture Complex, Thin-Ply Thermoplastic Tubular Composite Structures: An Experimental Case Study

PDF) Use of waste powder coatings as binders for the manufacture

Characterisation of the transverse shear behaviour of binder-stabilised preforms for wind turbine blade manufacturing - ScienceDirect

Permeability of the fabric preform in the out-of-plane direction.

Schematic representation of the assembly seam stitching pattern within

Polymers, Free Full-Text

Why Choose Binder Jetting? Experts Give Their Advice! - 3Dnatives

Advances of composite materials in automobile applications – A review - ScienceDirect