Research on the integral forming process of thin walled and thick

Comparison of thickness changes in experiments and FE simulation after

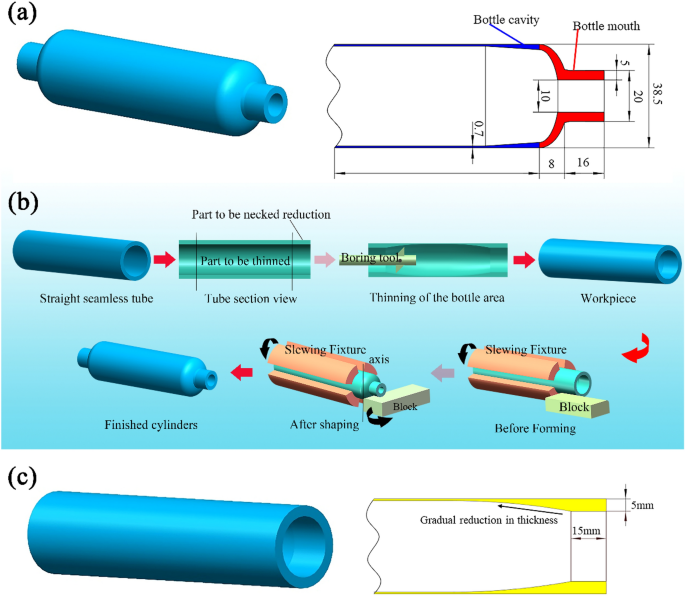

Research on the integral forming process of thin walled and thick mouth seamless gas cylinders

a) Illustration of dog-bone samples. Stress-strain curves of the brass

Finite element study of stress and strain state during hot tube necking process - Hamed Zoghi, Alireza Fallahi Arezoodar, 2013

History of hoop and meridional plastic strain changes with the roller

Variation of ovality along the length of the pipe: The dotted lines

Finite element study of stress and strain state during hot tube necking process - Hamed Zoghi, Alireza Fallahi Arezoodar, 2013

The flow behavior of the material annealed at 500°C for 1 hour with the

Typical failure modes in spin components [3].

Conventional manual spinning [15].

Response surface experimental and predicted values

Classification of spinning processes [3].

PDF] Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming

PDF) Research on the Integral Forming Process of Thin walled and Thick Mouth Seamless Gas Cylinders

Effect of (d/b) ratio on the deflection (w) for the internally loaded